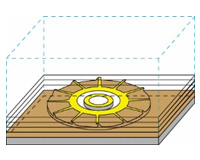

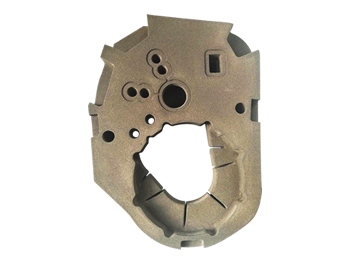

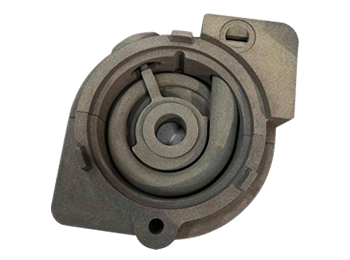

Our EPT 3D Printing facilitates the process of sand molding of foundry objects. Digital designs in CAD are readily 3D printed into sand molds that are not easy to be accomplished and modified by traditional molding methods. No more conventional tooling, plating and supporting structures are needed in heavily polluted workshop environment.

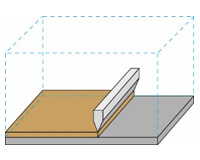

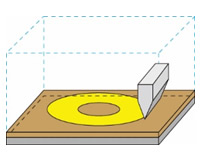

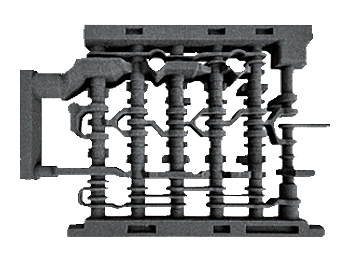

The 3D printing technology is mostly suitable for objects that are of complicated geometry, multiple angles and hollowness, traditionally such objects could be molded first in separate parts and assembled again into one final mold, now EPT 3D printing can mostly build whole sand mold once off in the single print bed.

Cost-effective and time-saving

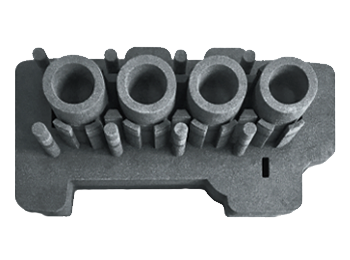

Mold/core accuracy tolerance within +/-0.3-0.5mm

No hassle for parts or prototype in less volume

Most applicable for objects with complicated geometry, hollowness and multiple angles

Visual CAD digital patterns quickly 3D printed into solid sand molds without concerns of conventional complications

High precision and high speed printing

In time of parts modification, only clicking in digital

CAD instead of tooling changes repeatedly

Volume in large build welcomed with same precision

Almost infinite free thinking in pattern designs, always available to be printed physically

Friendly to various metals in casting

… …